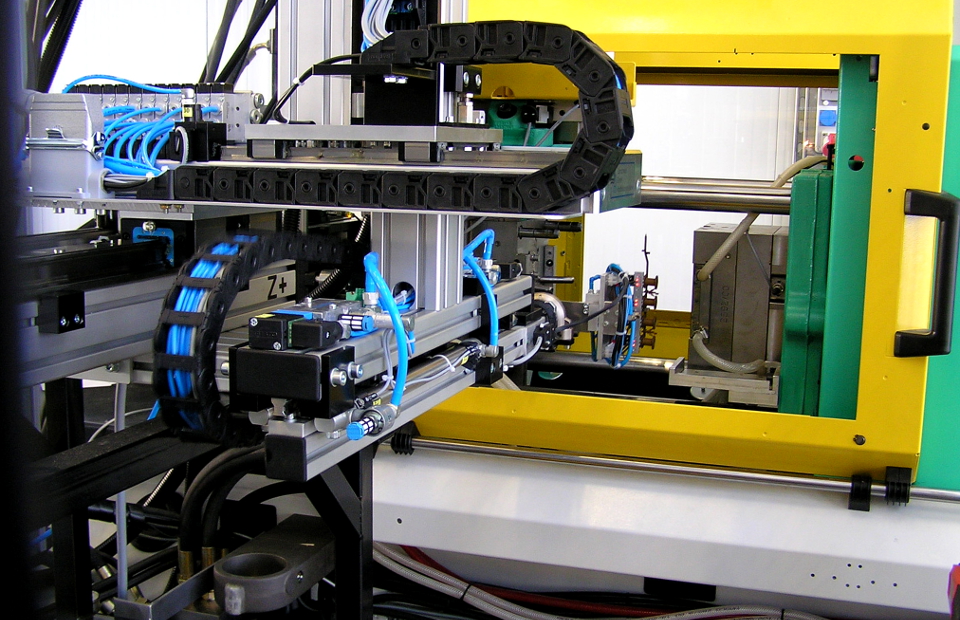

Side Entry

Extraction by Side Entry, Mounted on Non-Operator Side

TECHNICAL DATA

EG-CNC-mS

|

axis |

stroke/mm |

description |

drive |

Vmax. |

|

Z |

0 - 3000 |

Z-axis |

servomotor |

0,5 m/s |

|

Y |

0 - 1200 |

Y-axis |

servomotor |

2 m/s |

|

X |

0 - 400 |

X-axis |

servomotor |

1 m/s |

|

C |

90° |

rotating axis |

pneumatical 6 bar |

|

|

A |

90° |

rotating axis |

pneumatical 6 bar |

STANDARD EQUIPMENT

- easy use step-by-step control including diagnostic-tool

- quick-hitch system for gripper

- deposition of parts on non-operator-side

- load bearing capacity of gripper: 6 kg

- 2 vacuum circuits for gripper

- 2 pressure circuits for gripper

- 2 separate vacuum controls

- 1 5/2-solenoid-valve (monostable) for gripper

- 20 inputs (freely programmable)

- 3 outputs (freely programmable, potential-free)

- 20 outputs (freely programmable)

- synchronization with conveyor unit

- safety package for safety guard

QUALITY CONTROL (optional)

- start-up program: when starting or interrupting a cycle three shots (for example) will be deposited seperately

- reject: signal of injection molding machine - shot will be deposited seperately

- QA control: a complete shot will be deposited seperately for function check

CONTROL

- intuitive operation

- easy use programming (sequences, teaching, ...)

- diagnostic mode for inputs and outputs

- automatical error display

- sub programs

- parallel programs

+++

EG-ms4

|

axis |

stroke/mm |

description |

drive |

Vmax. |

|

Z |

0 - 1500 |

Z-axis |

pneumatical 6 bar |

1,5 m/s |

|

Z1 |

0 - 400 |

Z1-axis |

pneumatical 6 bar |

1 m/s |

|

Y |

0 - 400 |

Y-axis |

pneumatical 6 bar |

1 m/s |

|

X |

0 - 200 |

X-axis |

pneumatical 6 bar |

1 m/s |

|

A |

90° |

rotating axis |

pneumatical 6 bar |

STANDARD EQUIPMENT

- easy use step-by-step control including diagnostic-tool

- quick-hitch system for gripper

- deposition of parts on non-operator-side

- load bearing capacity of gripper: 2 kg

- 2 vacuum circuits for gripper

- 2 pressure circuits for gripper

- 2 separate vacuum controls

- synchronization with conveyor unit

QUALITY CONTROL (optional)

- start-up program: when starting or interrupting a cycle three shots (for example) will be deposited seperately

- reject: signal of injection molding machine - shot will be deposited seperately

- QA control: a complete shot will be deposited seperately for function check

CONTROL

- intuitive operation

- easy use programming (sequences, teaching, ...)

- diagnostic mode for inputs and outputs

- automatical error display

Contact

Dürrschmidt GmbH

Biberberger Straße 25 a

89284 Pfaffenhofen

Biberberger Straße 25 a

89284 Pfaffenhofen